Ensure Optimal Performance: Choosing the Right Komatsu Undercarriage Parts for Your Fleet

Wiki Article

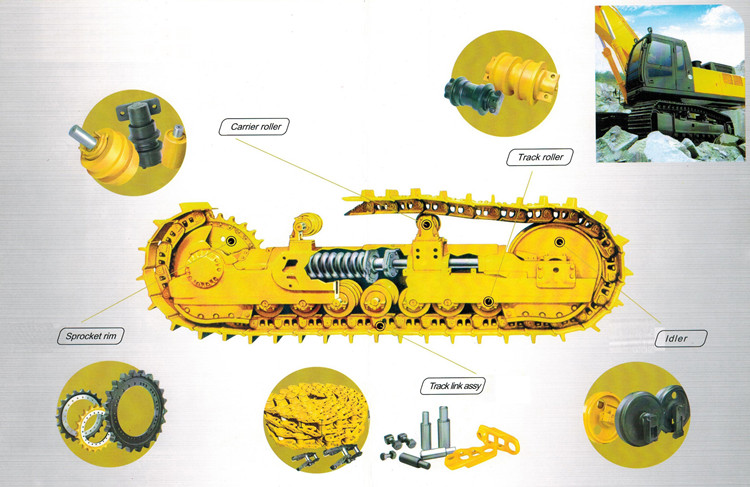

Trick Components: Undercarriage Components for Heavy Equipment

In the world of heavy equipment, the undercarriage offers as an essential foundation that guarantees the smooth operation and longevity of the tools. Key components such as track shoes, rollers, idlers, gears, and track chains play a pivotal function in the capability and efficiency of these substantial devices.Track Shoes

Track shoes play an important role in the efficiency and resilience of heavy equipment's undercarriage system. These elements are necessary for making certain traction, stability, and total performance of the devices. Track shoes can be found in various styles and materials to suit different operating problems and terrains. They are normally made from high-strength steel or other durable products to withstand the heavy tons and harsh environments that hefty equipment operates in.

The style of track footwear is engineered to provide ideal ground contact, minimizing slippage and boosting the device's ability to navigate tough terrains (komatsu undercarriage parts). Correct upkeep and routine inspection of track footwear are necessary to avoid premature wear and make sure the undercarriage system's durability. Any type of indications of wear, such as irregular wear patterns or extreme damage, should be addressed promptly to stay clear of expensive fixings and downtime

Rollers

To improve longevity and performance, rollers are normally constructed from high-grade materials like forged steel, supplying resistance to tear and use under heavy loads and harsh working problems. Appropriate lubrication is crucial to decrease rubbing in between the rollers and track shoes, extending the life-span of both components. Regular assessment and upkeep of rollers are necessary to protect against early wear and possible failures, making sure the constant procedure of hefty machinery.

Idlers

Idlers play an important function in the undercarriage system of heavy machinery, functioning as essential components for keeping proper track chain tension and making sure optimal device performance. Idlers are accountable for leading the track chain and supporting the weight of the devices. These cylindrical rollers are strategically placed along the track framework to disperse the device's weight evenly, minimize vibration, and enhance security throughout procedure.Properly functioning idlers assist avoid premature wear on the track chain and other undercarriage elements, inevitably expanding the life expectancy of the machinery. They also add to fuel efficiency by minimizing rolling resistance and lessening the energy required to move the tools. Routine examination and maintenance of idlers are essential to find any indications of wear, imbalance, or damages that could lead to efficiency problems or downtime.

Sprockets

Playing an important role in the undercarriage system of heavy machinery, sprockets are important parts accountable for transferring power from the equipment to the track chain. Sprockets include toothed wheels or equipments that mesh with the web links of the track chain, allowing the machinery to propel onward or backward. These parts are usually made from high-strength products like solidified steel to withstand the extreme pressure and rubbing produced during operation. Gears come in numerous dimensions and tooth configurations to match different maker specifications and applications. Appropriate maintenance and normal assessment of gears are crucial to make certain optimal efficiency and expand their lifespan. Problems such as damaged teeth or misalignment can cause reduced performance and possible failures. By comprehending the relevance of gears in the undercarriage system, drivers and upkeep employees can successfully take care of click for more these components to improve the general efficiency and integrity of heavy machinery.

Track Chains

An integral part of the undercarriage system in heavy equipment, track chains play a crucial role in sustaining and assisting the movement of the devices. Track chains are durable steel chains that connect the drive gear to the wheels or tracks of the heavy equipment (komatsu undercarriage parts). These chains are designed to withstand enormous tension, wear, and stress while ensuring smooth and try this website reliable operation of the equipmentTrack chains are composed of individual web links that are linked by bushings and pins. The style of track chains is crucial as it directly affects the total performance and toughness of the hefty equipment. Proper maintenance of track chains is vital to avoid early wear, reduce downtime, and prolong the lifespan of the equipment.

Routine evaluations, lubrication, and changes are needed to maintain track chains in ideal condition. Failing to maintain track chains can cause enhanced functional expenses because of regular replacements and fixings. Therefore, purchasing top notch track chains and sticking to a stringent upkeep routine is essential to making the most of the effectiveness and durability of heavy equipment.

Conclusion

In conclusion, the vital parts for hefty machinery undercarriage parts include track shoes, rollers, idlers, sprockets, and track chains. These parts are essential for the appropriate functioning and operation of hefty devices, offering stability, assistance, and grip. komatsu undercarriage parts. It is crucial for drivers and maintenance personnel to frequently evaluate and keep these parts to ensure the safety and efficiency of the machineryTrick components such as track shoes, rollers, idlers, gears, and track chains play an essential function in the performance and performance of these massive devices. Service provider rollers aid in supporting the weight of the equipment, while track rollers assist distribute the tons internet and ensure smooth track footwear articulation. Idlers act as a tensioning system for the track chain, maintaining correct track tension for optimal performance.

Track chains are durable metal chains that connect the drive gear to the wheels or tracks of the hefty equipment.In final thought, the vital elements for hefty machinery undercarriage components consist of track shoes, rollers, idlers, sprockets, and track chains.

Report this wiki page